Until recently, I had no idea what a Hayes Chronograph was. I didn’t even know it existed until Bill Lange (@BillLange1968) posted a picture of one on Twitter that linked to a wonderful article he wrote about them. The name Hayes was instantly recognizable though, being the inventors of the Hayes “AT” Command set that has found a way into just about every modem since. The shape was also familiar, a bigger version of the same case used in their Smartmodem 300. This was different. It had a beautiful vacuum fluorescent display (VFD) that was showing the current time and day of the week. I was hooked. I needed to buy this. What a wonderful trophy from the soon to come BBS halcyon days.

Continue readingCategory Archives: Uncategorized

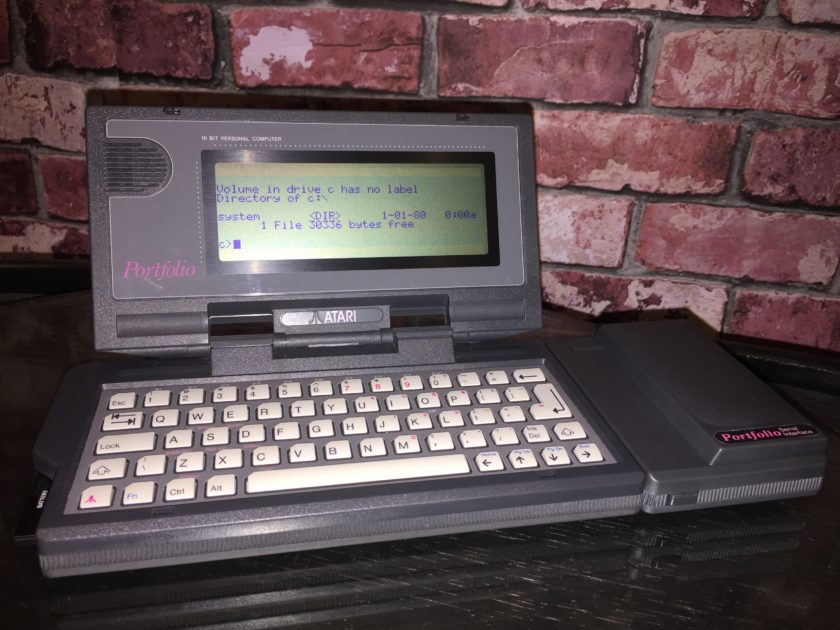

Atari Portfolio Serial Interface: How To Get Terminal Software

I’ve had an Atari Portfolio HPC-004 for a couple of years now. It’s a slick little palm-top: solid state memory, MS-DOS compatible, 4 AA batteries as power source. It also has a docking slot on the right side for extra peripherals. This enables you to add communications ports that are otherwise lacking like a parallel or serial port. I’ve been seeking a second hand serial interface (HPC-102) for some time but have come up empty. I decided to instead purchase one new.

Convert a Commodore 64 from NTSC to PAL format

If you’ve ever used a NTSC Commodore 64 for any length of time, you’ll quickly find out that many games and demos you try to run on your machine sometimes exhibit strange graphic or sound glitches or just refuse to run properly at all. It’s most likely because the program you’re trying to run was originally written on a PAL machine. With it’s different VIC-II chip generating a different master clock signal, the PAL C64 has a few more cycles available per frame than the it’s NTSC counterpart. Tightly coded loops in programs rely on a certain number of cycles to be available. And when they’re not, well, it doesn’t work as intended.

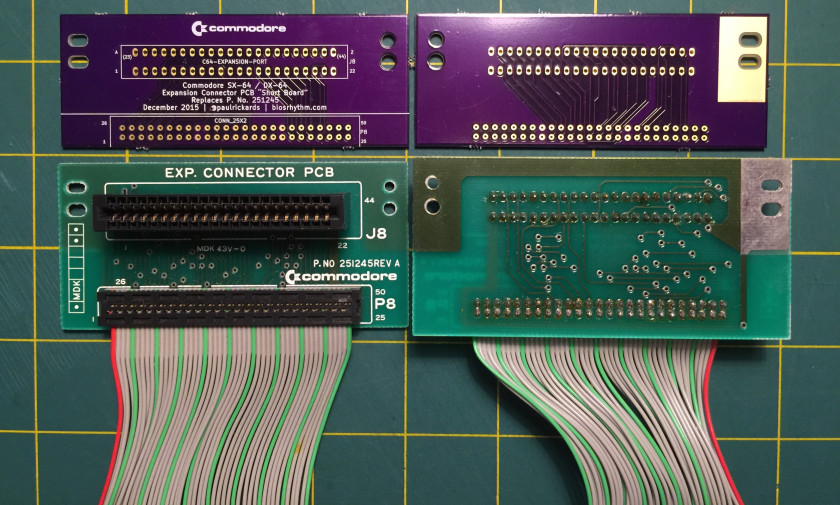

If you happen to own a C64 “short board” system, you can convert your NTSC machine to a PAL one easy. If you are unsure which board you have inside, you can open it up and take a look or make an educated guess by reading this site. A SID 8580 is usually a good sign you have a short board. But please make sure you confirm your board type before you begin. The VIC-II types (65xx vs 85xx) are not interchangeable!

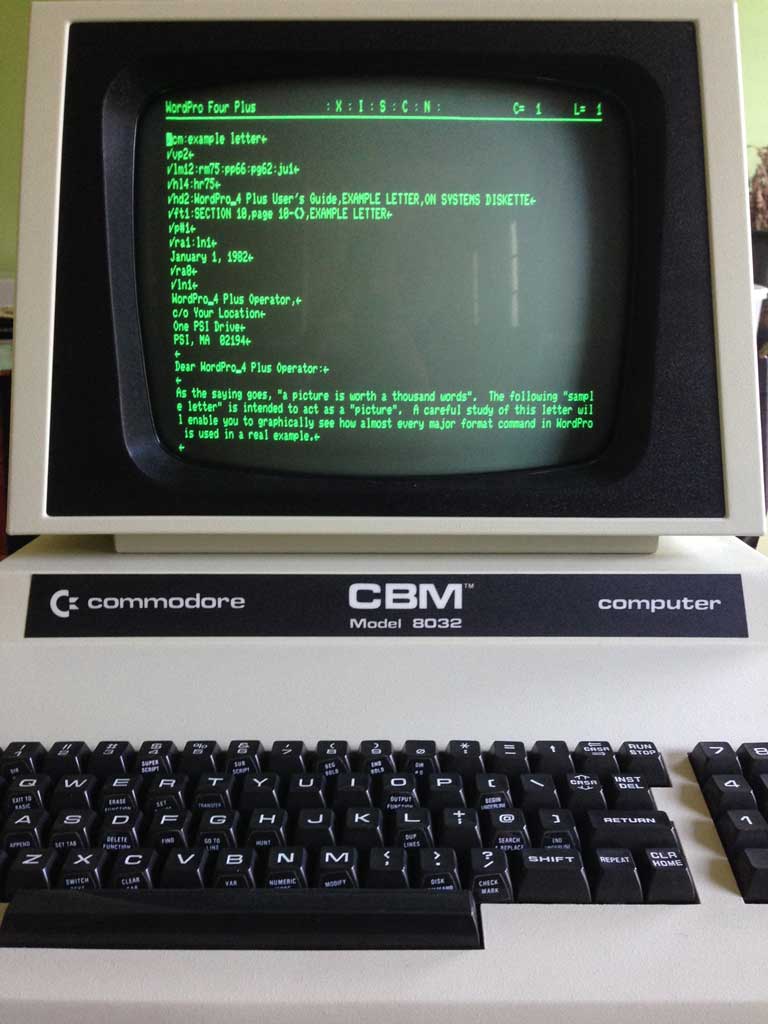

Continue readingRS-232 for Commodore PET and Dialing a BBS over WiFi

I’ve owned a Commodore PET* 8032 for a few years now. I’ve been able to download and run many different programs for it, like WordPro you see above. But one thing always remained elusive. I’ve long wanted to connect it to a standard RS-232 device and use it as a terminal. The PET’s classic shape, green monochrome monitor, and 80 column display all lend itself perfectly as a terminal.

Continue readingLumaFix64: Commodore 64 with less stripes

You might be asking yourself, less stripes? No, not the colorful stripes on your breadbin badge. We’re talking about the stripes on the video image. The same stripes that we’ve all become accustomed to over the many years of playing Commodore 64 games, watching demos and carrying on with modems and BBS’s. These stripes, which are actually interference, come in a variety of flavors: horizontal, vertical, and checkerboard patterns. The intensity of the stripes also varies from machine to machine. Some say with that these stripes become even more apparent when using a C64 with a modern LCD monitor.

SX-64 Short Expansion Board

If you were following along with my previous post about converting an SX-64 to a DX-64 by adding a second floppy drive, you’ll know that the process isn’t without it’s problems. There are some irreversible changes that need to be made to the case to accommodate all the extra equipment.

Continue readingConverting a Commodore SX-64 to a DX-64 Dual Drive

Many floppy. Very retro. Such storage. Wow. #doge #c64

The SX-64 was Commodore’s portable version of the best selling C64 computer that wrapped the C64, a 5″ color display and a 1541 floppy drive into one case that loosely resembled a Kaypro. They were also called luggables because, well, they are quite heavy. Despite folks calling them rare, they litter eBay very frequently and command a premium price.

DIY Foam Packaging

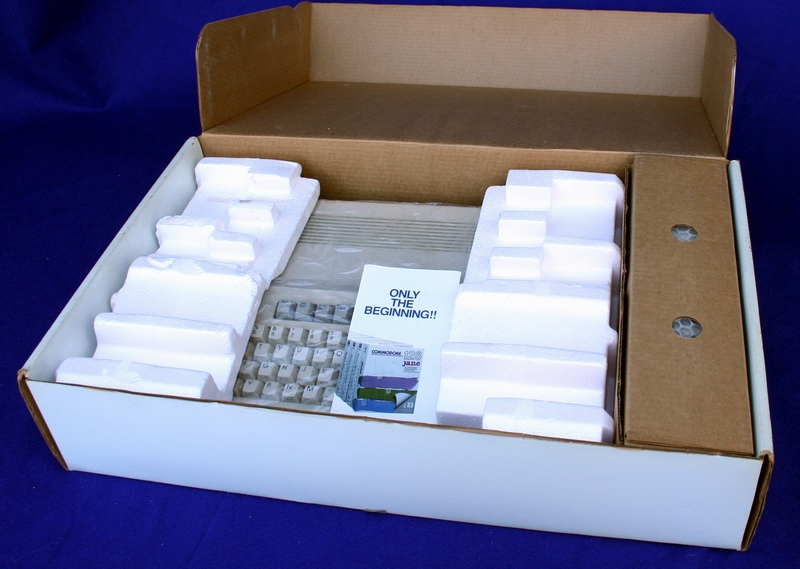

It’s time to de-clutter once and again and that means time to visit eBay. First item I’m parting with is a nice Commodore 128 and 1571 disk drive. I have the original box for the CPU but that’s about it for the packaging. I don’t have the original foam sides that held the computer in place (see picture below).

Instead, my computer looks more like this.

I need a good way to keep the computer from getting damaged inside the original box before that box goes in another box– follow me? That got me thinking about the expanding foam in a bag system I’ve seen before. It’s foam that expands inside a plastic bag– place it inside the box and close the lid and it fills the voids and holds everything in place. I wondered if a can of “Good Stuff” expanding foam insulation would work. I picked up a can (large gap filler) for a $5er.

I have these nice cardboard corners as starting points– but they’re a little big. My plan was to fill the corners with foam, put a bag over it and put the computer inside it and let the foam do it’s magic. The results so far look promising.

Some things I’ve noticed–

- It expands slowly, so don’t rush, you’ve got hours before it cures.

- Make sure to put at least two pieces of plastic between the foam and your object to keep it safe.

- Don’t over do it– remember, it will expand.

- Wear gloves!

- Some areas seem to be taking a long time to cure. The bottle says water speeds the process.

Memories Of The Future- Select Start Records Compilation

Frog Fail!

I recorded a high speed (or slow motion) movie of this frog. I wanted to capture him jumping into the pond but that’s not what he had in mind.