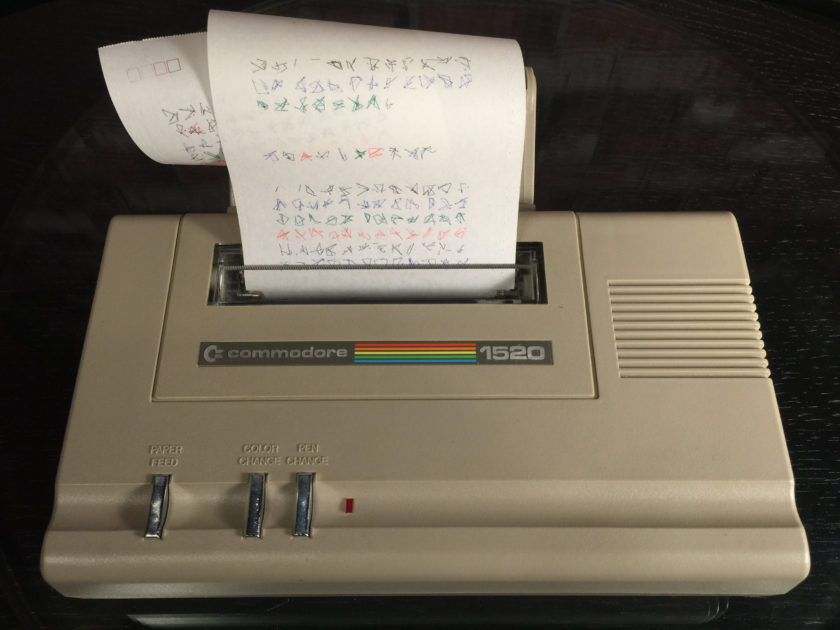

You’ve just unpacked your new Commodore 1520. It was most likely sold as untested, as-is or condition unknown. You plug in the cable, turn it on, and it buzzes and grinds for a couple of seconds then the red LED on top flashes. Silence. You might be lucky and get a little movement on the print head.

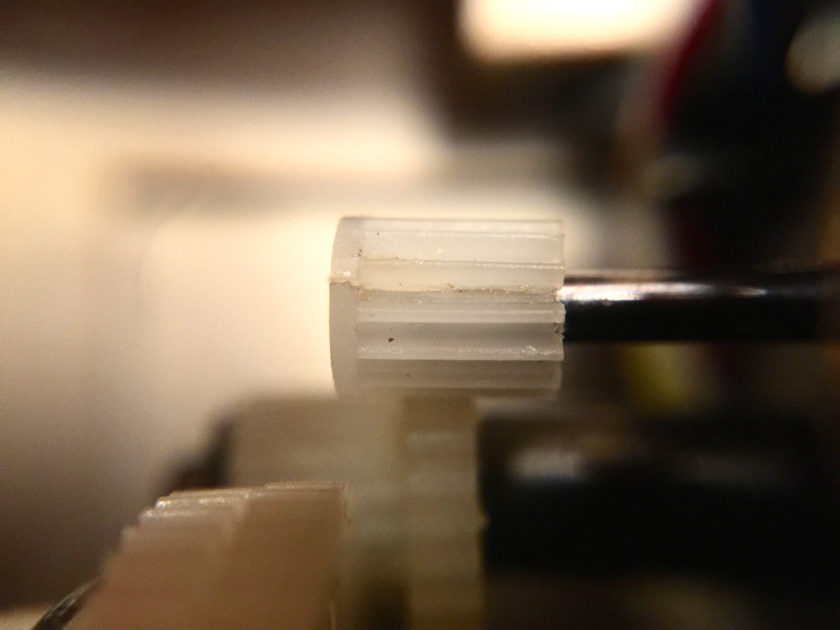

While the diminutive Commodore 1520 Printer/Plotter looks as good as the day it was made over 30 years ago, one specific part suffers over time. Two actually. Inside, the Alps printer mechanism contains two small stepper motors. You can’t see them– they’re inside the silver platen housing. On the left and right side, the stepper motor shaft sticks out and has two small gears attached to them. These gears (most likely made of nylon) have shrunk in size and split apart under the pressure of the spindle. There’s now a gap in one of the 13 teeth and it binds against the opposite gear causing the grinding sound you hear at start up.

Replacements are available. Best Electronics sells via email order a set of 2 replacement gears for $15 with a $20 minimum. That’s likely as much as you paid for the plotter.

You can also repair the split with glue, but not in the way you might think. We’re not going to try to get glue in between the split as that would be nearly impossible due to their tiny size. What we need to do is minimize the effects of the gear shrinking in size. If you remove the gear from the motor spindle, you’ll notice the split closes. This is because the gear bore is slightly smaller than the motor spindle. It’s pressure fitted. You’d normally want this as it transfers the motor force into the gear.

But if we increase the bore size of the gear, the spindle won’t force apart the split any more. Unfortunately it now freely spins on the spindle. Using some super glue on the spindle, you effectively mechanically connect the gear to the spindle again plus hold the split “closed” from the inside of the bore without the risk of getting glue in the teeth.

Here are the steps I follow.

- Remove the old gears from the spindles. Be careful not to damage the opposing gears in the process. You can very gently move the spindle towards the back of the case with a flat head screwdriver in one hand and slip the gear off with the other.

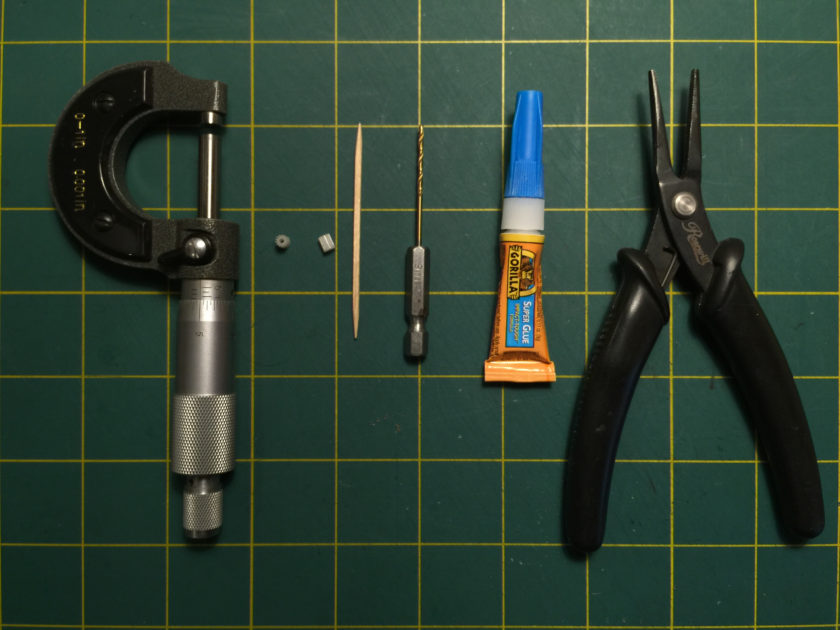

- Locate the split in the gear. Gently clamp the gear making sure the gap/split has pressure pushing it together. I used a small caliper to do this.

- Using a 1/16 inch drill bit, BY HAND, slowly and gently drill the bore until the bit goes all the way through. Clean up any debris with a toothpick.

- Note that one side of the gear has a closed, flat edge. This will now face away from the motor. Slip the gear on the spindle and test it. Hopefully the split should no be visible and the gears should rotate freely without any binding or even pauses. Remove the gear from the spindle.

- Apply a tiny dab of super glue on the spindle motor and slip the gear on. With your fingers, roll the opposite gear back and forth. This will distribute the glue around the spindle, stop with the split facing up.

- Using needle nose pliers, gently close the gap if there’s one until your glue sets. Gorilla Glue says 30 seconds.

- Let it sit over night for the best bond.

It should be noted that many computer companies in the early 1980’s had a plotter that used the same Alps plotter mechanism. They are the Atari 1020, Tandy CGP-115, Oric MCP40, Sharp CE-150, and probably others. These instructions most likely will serve you well with those machines as well.

I’ve repaired about 5 Commodore 1520 plotters, a CGP-115 and two Atari 1020s using this method. Out of all of them, I had one fail again after heavy use. Your mileage may vary.

Some tips that will keep your plotter working longer:

- Always remove and cap the pens when you’re done using it.

- When you’ve removed all the pens, power off the printer with the pen carriage all the way to the right (in pen replace mode).

- When you power it on the next time, it won’t grind against the left stop as it tries to find “home.”

- If you don’t have the paper spool holder, a standard round pencil works perfectly.

As with all things you find online, what you choose to do to your own equipment is your own choice. I won’t be held responsible for anything you damage (including your equipment or yourself). Use common sense and do your research before attempting any kind of repair.

Let me know in the comments if you successfully repaired your plotter, have an alternate fix or know of a source for replacement gears.

Mitchell Farley

April 29, 2016 at 2:09pmHello Paul. This is “aphexteknol” from youtube. Been having fun today trying out some programs you linked me to on my 1520. I was curious about your SVG converter. I would really love to do a demo on the 1520 plotter later this year at VCF Midwest, and being able to plot some interesting things without a terrific amount of BASIC programming in some manner would be absolutely fantastic. Thanks again for putting this information online for everyone. -Mitchell

RizThomas

May 9, 2016 at 10:43pmHello Paul,

Thanks for sharing your “Fix” on the 1520 gears. I have manage to fix my two 1520 but when they split again, I”ll try your way.

I also had a CGP-115 which had the same problems with the gear. However, I managed to buy a set from Best Electronics so I used that on the CGP-115.

Another tip i got from Best Electronics regarding the pens. When not in use ( or if you have some spare around), apparently storing them in the fridge will prolong the ink life.

Brian K. White

April 25, 2017 at 7:53amAfter spending a bejillion hours putting this together last year:

http://tandy.wiki/CGP-115

I am super glad to hear about these new plastic gears instead of the brass ones I found.

Now we just need the pens. I did find a source of new pens, not old sock, but they are pretty expensive for how short they live. Although they are somewhat refillable with insulin syringes and water based plotter pen ink. lasse-shop.de

Thank you very much for putting this together. Awesome!

Dan Henderson

November 27, 2017 at 11:03amThis is great stuff! I’ll need to order a set of gears for my 1520. BTW, do you happen to know whether the Alps Mechanism in the Atari 1020 is interchangeable with that found in the Commodore VIC 1520?

Thanks

Dan

paulrickards

November 27, 2017 at 7:33pmYes, the Alps mechanisms are the same. The connections to the internals are slightly different but easily adaptable.

Dan Henderson

December 1, 2017 at 8:27pmThanks! I just received and installed a NOS mech from Best Electronics. Everything was working great through several prints of the user manual example programs. Now suddenly the same prints are not printing accurately. Argh! I’m wondering if one of the spur gears have split. A cursory look didn’t reveal any splits. I’ll need to take a closer look later when I have time.

Dan Henderson

December 2, 2017 at 9:36amWell, as it turns out my printer is working just fine. I believe the issue had to do with the plotter pulling paper off the roll — to much resistance.

Peter Risse

June 5, 2018 at 3:28pmHallo.Wo bekomme ich diese Zahnräder 13 Zähne fürmeinen Drucker Sharp EA 140.Würd gerne 10 Stück kaufen.Schon jetzt vielen Dank für die Hilfe.

paulrickards

June 23, 2018 at 4:29pmThe gears here may fit your Sharp EA 140. https://www.shapeways.com/product/CMBQ6D2Z4/alps-x-y-plotter-gear-qty-3-commodore-atari

David Given

August 6, 2020 at 9:07amI have a CGP-115, which is faulty, but bizarrely my nylon gears are fine and instead the stepper motors have failed — I think the bearings have died (unless I apply longitudinal pressure to the motor shafts I get no torque). Do you have any idea what kind of motors these plotters use and if I can get replacements?

Eddie

July 20, 2021 at 7:47pmThanks very much. Worked great.

Walter Hynson

June 2, 2024 at 5:27pmI have a bid on one of these plotters ,I plan to remove all old electronics a use an arduino UNO running GRBL to drive it ,I also plan to redesign and 3d print a new pen holder whinh will be raised and lowered via micro stepper motor mechansim from foo Ali Electronicts ,more than likely I will have to make anothe case for it also.